Product Description

11kV 15kV 20kV 33kV 35kv Medium Voltage single core 3 core Copper Aluminum Conductor XLPE Insulated Armoured electrical Power Cable

1. Product Standard

This product is manufactured according to GB/T12706.2, equivalent to IEC60502.2. Or BS, DIN, ICEA standard as customer request.

2. Application

The product is suitable for use in power transmission and distribution lines with rated power frequency voltage 3.6/6kv~26/35kv.

3. Operating characteristics

- Rated power-frepuency voltage U0/U: 3.6/6kv~26/35kv.

- Max.admissible operating temperature of the conductor:90ºC.

- Max. short-circurt temperature of conductor shall not exceed 250ºC. (5s maximum duration)

- The ambient temperature under installation should not below 0ºC.

- The bending radius of a single-core cable should not less than 20 times of the cable diameter.

The bending radius of a multi-core cable should not less than 15 times of the cable diameter.

4. Table of the voltage, cores and cross-section

|

Item

|

Category A ,B

|

3.6/6kV

|

6/10kV

|

8.7/15kV

|

12/20kV

|

18/30kV

|

21/35kV

|

|

Category A ,B

|

6/6kV

|

8.7/10kV

|

12/15kV

|

18/20kV

|

-

|

26/35kV

|

|

Single core

|

mm2

|

25-1200

|

25-1200

|

35-1200

|

50-1200

|

50-1200

|

50-1200

|

|

Three core

|

mm2

|

25-400

|

25-400

|

35-400

|

50-400

|

50-400

|

50-400

|

The cable with Category A rated voltage is used in the situation requiring not over 1 min. of grounding fault lasting time. For the cable with Category B rated voltage, the grounding fault lasting time normally is not over 1 hour, max. lasting time is not over 8 hours, annual ground fault lasting time altogether should not be over 125 hours, Category C includes all the system expect Category A and B.

5. Type and Name

|

Type

|

Designation

|

Applications

|

|

YJV

|

Copper conductor,XLPE insulated,PVC sheathed power cable

|

For laying indoors,in tunnel or cable trench,unable to bear external mechanical forces.Single core cable is not allowed to laid in magnetic duct.

|

|

YJLV

|

Aluminum conductor,XLPE insulated,PVC sheathed power cable

|

|

YJY

|

Copper conductor, XLPE insulated,PE sheathed power cable

|

|

YJLY

|

Aluminum conductor, XLPE insulated,PE sheathed power cable

|

|

YJV22

|

Copper conductor,XLPE insulated,steel tape armoured,PVC sheathed power cable

|

For laying indoors,in tunnel in cable trench,or direct in ground,able to bear external mechanical forces.Single core cable is not allowed to laid in magnetic duct.

|

|

|

YJLV22

|

Aluminum conductor,XLPE insulated,steel tape armoured,PVC sheathed power cable

|

|

|

YJV23

|

Copper conductor,XLPE insulated,steel tape armoured,PE sheathed power cable

|

|

|

YJLV23

|

Aluminum conductor,XLPE insulated,steel tape armoured,PE sheathed power cable

|

|

|

YJV32

|

Copper conductor,XLPE insulated,steel wire armoured,PVC sheathed power cable

|

For laying indoors,in tunnel cable trench,well or direct in ground,able to bear external mechanical forces and certain pulling force.

|

|

|

YJLV32

|

Aluminum conductor,XLPE insulated,steel wire armoured,PVC sheathed power cable

|

|

|

YJV33

|

Copper conductor,XLPE insulated,steel wire armoured,PE sheathed power cable

|

|

|

YJLV33

|

Aluminum conductor,XLPE insulated,steel wire armoured,PE sheathed power cable

|

|

SWA Armoured 3-core cable with XLPE insualtion. Rated voltage 18/30(36)kV 19/33(36)kV Cable Date

|

Conductor

|

Insulation thickness (mm)

|

Copper tape screen (approximate) (mm)

|

PVC

bedding thickness (mm)

|

Armored wire diameter (mm)

|

Sheath thickness (mm)

|

Outer diameter (approximate) (mm)

|

Copper core cable weight (kg/km)

|

Aluminum core cable weight (kg/km)

|

|

Cross sectional area (mm2)

|

Structure

|

Outer diameter (mm)

|

|

50

|

Compact round

|

8.4

|

8.0

|

0.1

|

1.8

|

3.15

|

3.5

|

77.3

|

9333

|

8390

|

|

70

|

Compact round

|

10.0

|

8.0

|

0.1

|

1.8

|

3.15

|

3.6

|

80.9

|

10396

|

9075

|

|

95

|

Compact round

|

11.7

|

8.0

|

0.1

|

1.9

|

3.15

|

3.7

|

85.0

|

11723

|

9930

|

|

120

|

Compact round

|

13.1

|

8.0

|

0.1

|

2.0

|

3.15

|

3.8

|

88.4

|

12986

|

10720

|

|

150

|

Compact round

|

14.6

|

8.0

|

0.1

|

2.0

|

3.15

|

3.9

|

91.8

|

14220

|

11388

|

|

185

|

Compact round

|

16.3

|

8.0

|

0.1

|

2.1

|

3.15

|

4.0

|

95.9

|

15887

|

12395

|

|

240

|

Compact round

|

18.5

|

8.0

|

0.1

|

2.2

|

3.15

|

4.2

|

101.2

|

18144

|

13613

|

|

300

|

Compact round

|

20.7

|

8.0

|

0.1

|

2.3

|

3.15

|

4.4

|

107.0

|

20761

|

15097

|

|

400

|

Compact round

|

23.8

|

8.0

|

0.1

|

2.4

|

3.15

|

4.6

|

114.3

|

24824

|

17273

|

|

500

|

Compact round

|

26.6

|

8.0

|

0.1

|

2.5

|

3.15

|

4.8

|

122.2

|

29019

|

19580

|

We have alarms on extruding insulation andjacket, to keep 100% quality.

Founded in 1994, Fujian Suke Cable Technology Co., Ltd. Decades of wire and cable manufacturing experience enables us to be one of Top 20 cable manufacturers in China. Our products cover low/medium/extra high voltage power cable, submarine cable, control cable, instrumentation cable, building wire, flexible rubber cable, fire rated cable, renewable cable, solar cable, industrial cable, LAN cable, coaxial cable etc, a total of nearly 30 series with 4,000 types and more than 50,000 specifications for various fields within over 100 countries.

10

No. of Production Lines:Above 10

7

Number of Foreign Trading Staff:7

3

The company has 3 factories

Our workshops and certifications

Our company has three plants possessing 200 square kilometers and over 4500 employees with 130 technicians creating annual export revenue exceeding 150 Million USD.

Also, our company has passed ISO 9001, ISO 14001, ISO45001, OHSAS18001,etc certificatiom, and has got CCC,TLC, TUV, VDE, UL, CE, SAA, BS etc. certificates for our products.

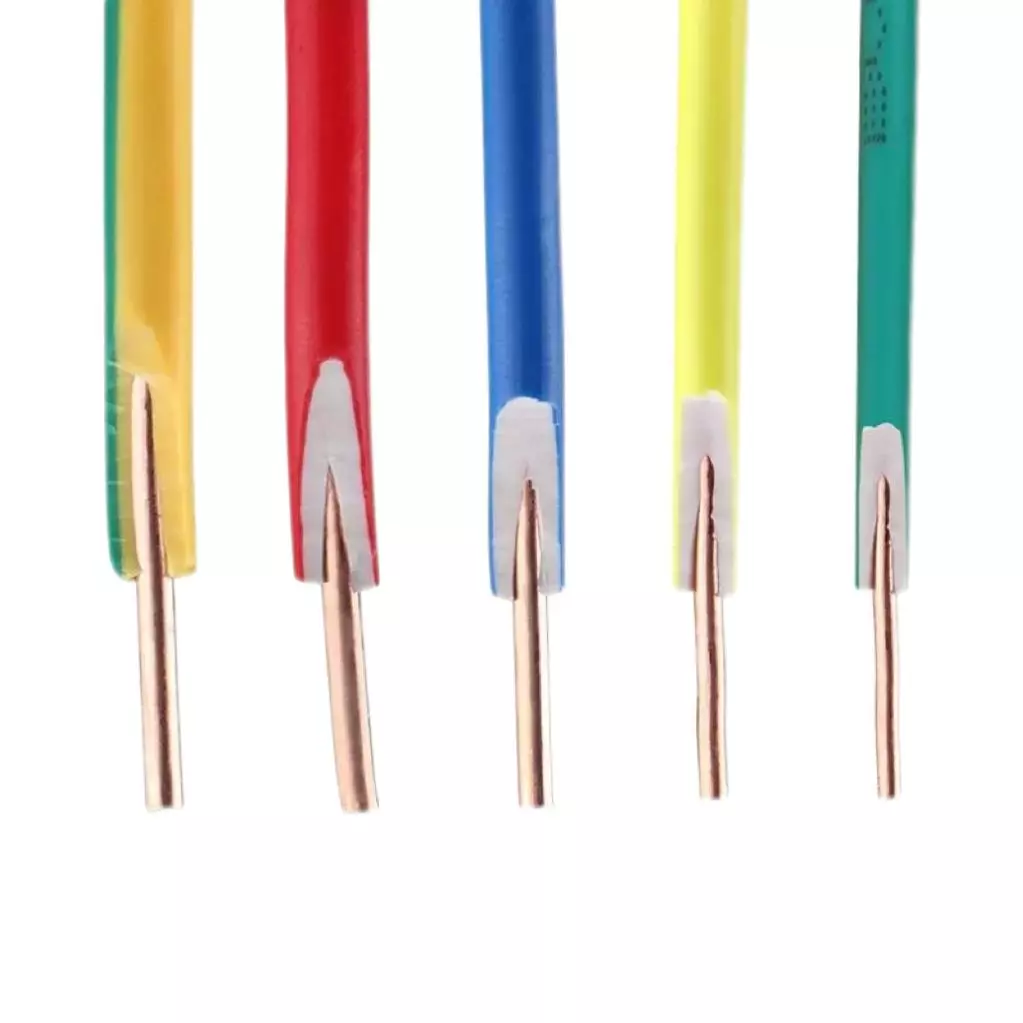

Building wire is generally used in house fixed wiring. It is PVC insulated unsheathed electric wire. The onstruction is CU/PVC.

How do I know if a cable is compliant with standards?

Look for certification marks or labels on the cable, such as those from IEC, UL, or other relevant regulatory bodies that indicate compliance with safety and performance standards.

What are armoured cables?

Armoured cables have an additional layer of protection (usually metal) to prevent physical damage. They are often used in harsh environments or where cables may be exposed to impact.

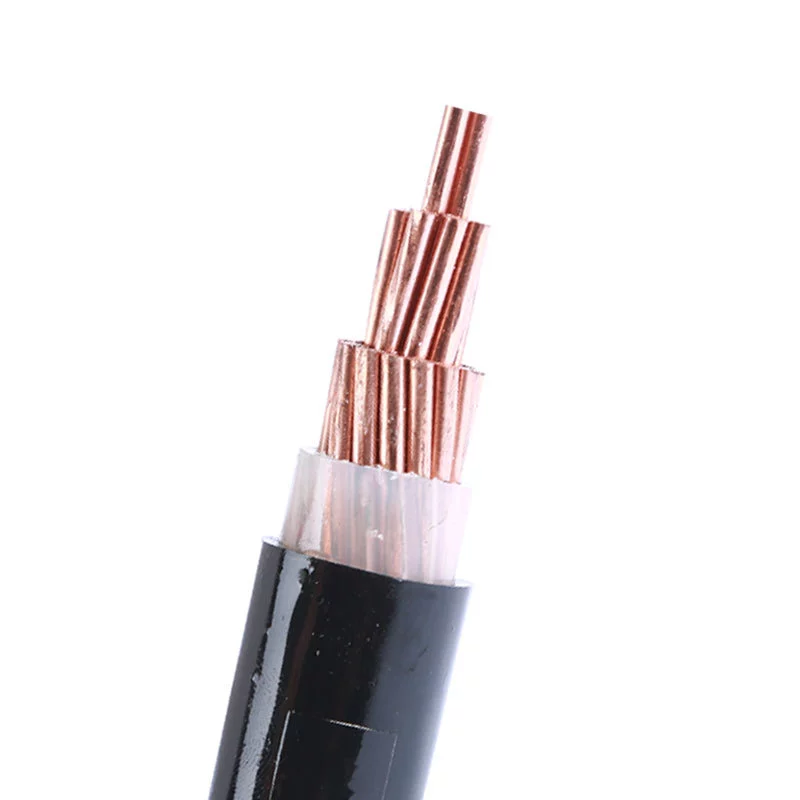

Conductor Structure of Power Cable

1. Conductors comply with IEC, AS/NZS and BSI standard requirements

2. The conductors of multi-core have different shapes. The single-core is circular. The shape of Multi-core cable with size up to and 35m2 can be circular, semicircular and fan-shaped, the conductor with size over and 50m2 are circular and semicircle.

3. A single core is allowed with size below 16m2. Conductor More than 25m2 are multi strands.

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address