EPDM Cable: Ideal Cable Solution for New Energy and Extreme Environments

Jun 17,2025

Jun 17,2025

Suke

Suke

As the global energy structure continues to transform towards cleaner and renewable energy, the cable industry is also undergoing profound changes. Especially in the fields of new energy, rail transportation, electric vehicles, wind power, photovoltaic and high-temperature industry, the performance of cables is more demanding. EPDM Cable (Ethylene Propylene Diene Rubber Insulated Cable) is becoming the preferred solution for cables used in a variety of extreme environments due to its excellent resistance to heat, ozone, water and flexibility.

What is EPDM Cable?

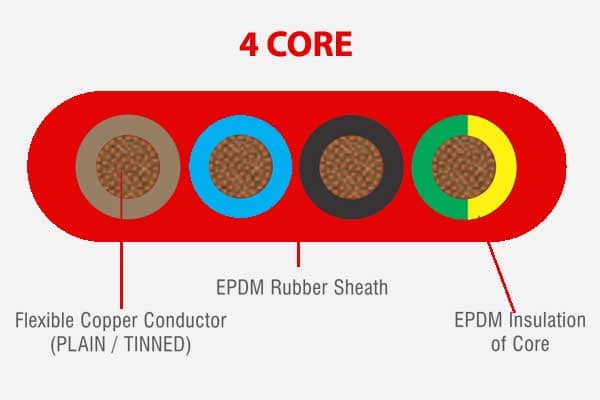

EPDM, or Ethylene Propylene Rubber, is a synthetic elastomer with excellent thermal stability, aging resistance and electrical insulation properties.EPDM cable is typically used in applications that require long-term resistance to high temperatures (up to 120°C or even 150°C), UV, ozone and water. Its structure can include single or multi-core conductors, and the outer sheath can be made of PVC, rubber or other modified materials according to the application requirements.

Industry Application Trends of EPDM Cables

1. New Energy and Energy Storage Systems

With the large-scale landing of photovoltaic and energy storage projects around the world, the market demand for flexible, high-temperature-resistant cables continues to rise. EPDM cables are very suitable for laying in complex environments, such as solar panel racks and the inside of energy storage cabinets, due to their good flexibility and long-term heat-resistant properties.

2. Railway transportation and subway system

In urban rail transportation, cables need to be flame retardant, low smoke and non-halogen, oil resistance, mechanical impact resistance, etc. EPDM sheath not only improves safety, but also reduces maintenance frequency and extends service life.

3. Wind power/offshore engineering

Wind turbines operate in harsh environments, especially offshore wind power, often facing challenges such as salt spray corrosion, high humidity, and large temperature differences, etc. The excellent environmental resistance of EPDM materials can guarantee the stable operation of cables in wind towers, nacelles and other parts.

Market demand growth: EPDM cable ushered in the “window period”

According to the “Global Wire and Cable Market Report” analysis, EPDM cable market will expand at a compound annual growth rate of more than 5%, especially in the Asia-Pacific, the Middle East and Latin America, infrastructure upgrades and new energy projects intensive start-up become a strong driving force. In particular, infrastructure upgrades and intensive new energy projects in Asia-Pacific, the Middle East and Latin America will be a strong driving force.

In the field of electric vehicles and charging piles, EPDM cables are also gradually replacing traditional PVC and TPE cables for high-voltage connection systems and fast-charging cables to enhance the safety level.

Why choose EPDM Cable?-Core Advantages

High Temperature & Ozone Resistance: Stable operation under high temperature/high UV environment for a long time;

Excellent flexibility: easy wiring and installation, suitable for narrow or moving parts;

High insulation strength: stable electrical performance, suitable for medium and high voltage applications;

Green and environmentally friendly: optional low-smoke, no-halogen (LSZH) formula, in line with international environmental standards.

Suke Cable: Providing you with reliable EPDM Cable solutions

As a leading industrial cable manufacturer in China, Suke Cable focuses on providing professional cable solutions for new energy, power, transportation, offshore and other industries. Our EPDM insulated cable series comply with many international standards such as IEC, UL, GB, etc. Our products are certified by TUV, CE, etc. We support OEM/ODM customization.

Our products are widely used in key projects at home and abroad, especially in extreme environment wiring, high temperature connections, and corrosion-resistant power systems.

Conclusion: EPDM is a key player in the new era of cables

In the foreseeable future of technological change, EPDM cable will become a key component in multiple industries to enhance the safety and operational reliability of equipment. Whether in the new energy wave or in extreme engineering environments, choosing EPDM cables means choosing performance, reliability and long-term benefits.

If you are looking for high-quality EPDM cable suppliers, welcome to contact Suke Cable for professional technical support and customized solutions.

Home

Home

Exploring the Intricate World of Electrical Cables From Construction to Applications in Modern Technology

Exploring the Intricate World of Electrical Cables From Construction to Applications in Modern Technology  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address