Key attributes

Industry-specific attributes

Application: residential wiring

Conductor Material: Copper

Conductor Type: Solid

Insulation Material: PVC

Other attributes

Place of Origin: Fujian, China

Brand Name: Suke

Model Number: NMD90

Type: insulated

Core: multi core

Rated Voltage: 300V

Rated Temperature: -25℃ MIN, 90℃MAX

Standard: CSA

Product Description

•Use and installation

NMD90 cables may be used for both exposed work in dry locations or concealed work in dry or damp locations.The maximum allowable conductor temperature is 90°C. The minimum recommended installation temperature is -25°C for two-conductor cables and -10°C for three-conductor cables (with suitable handling procedures). Material should be properly stored above 0°C for 24 hours prior to installation. The maximum voltage rating for all intended applications is 300 volts. Consult the Canadian Electrical Code1 for further information related to applications.

•Specification

Type NMD90 cable complies with:

ASTM

C22.2 No. 48 (non-metallic sheathed cable)

Canadian Electrical Code1

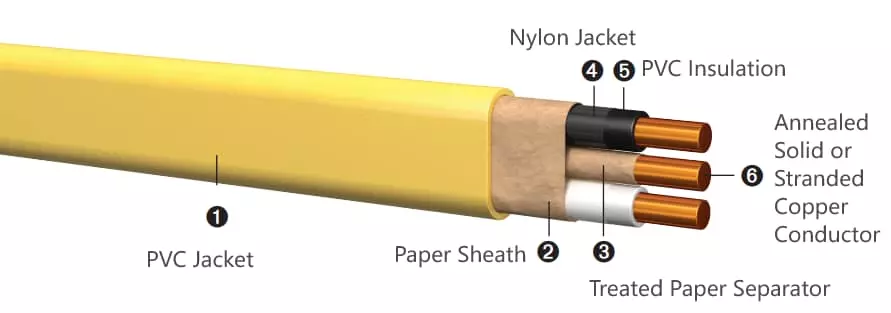

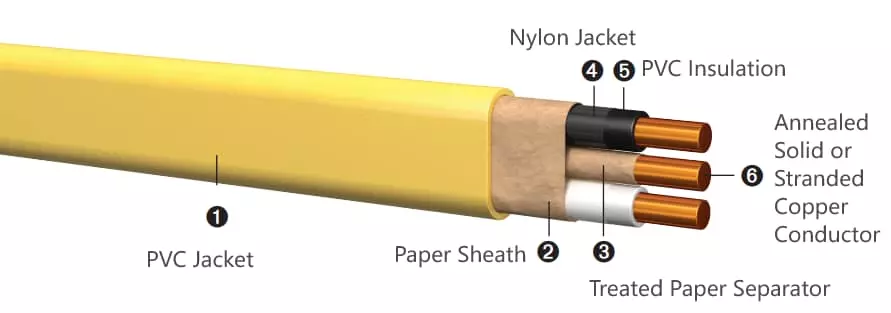

•Structure

NMD90 cables are available as two- or three-conductor cables with a bare grounding conductor. It is manufactured using annealed (soft) copper conductors—compressed standing for stranded conductors; a heat-resistant thermoplastic polyvinyl chloride (PVC) insulation and nylon jacket for the individual conductors with a PVC jacket for the overall construction.

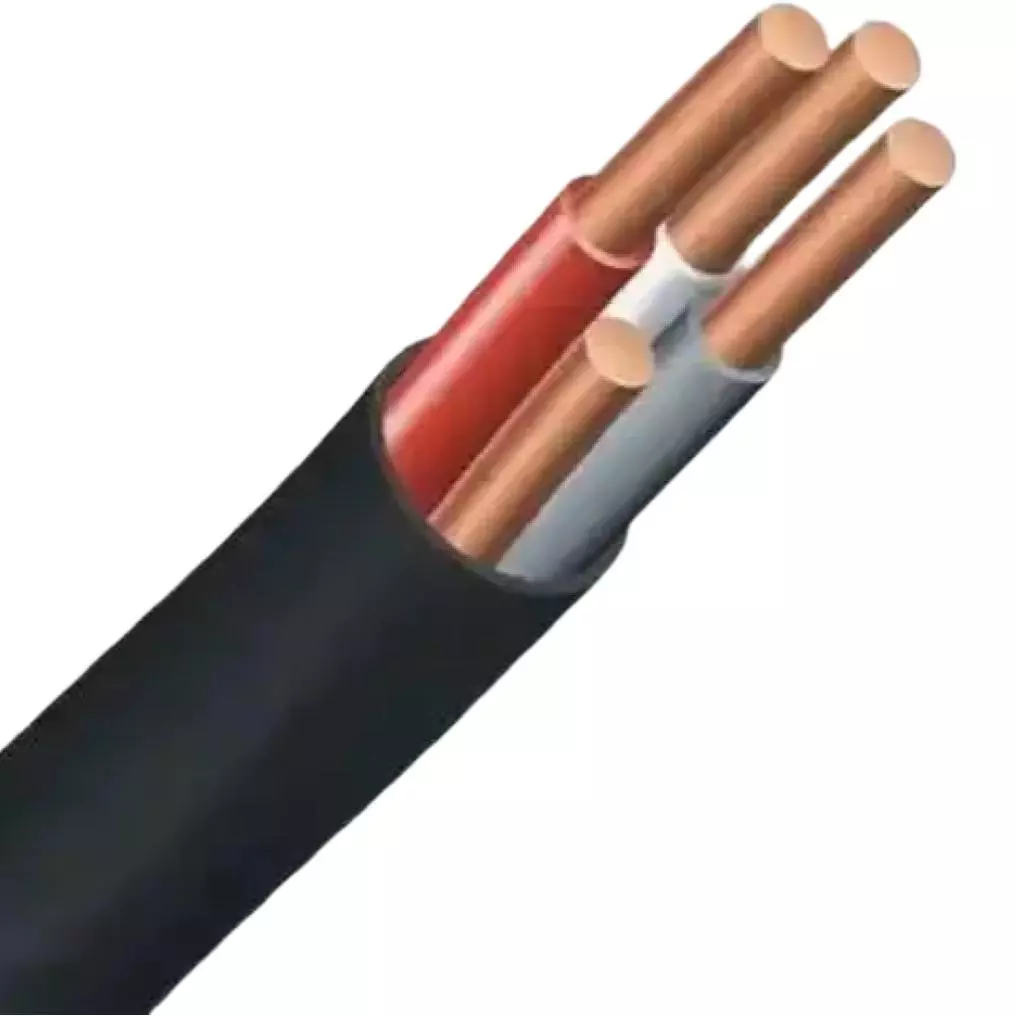

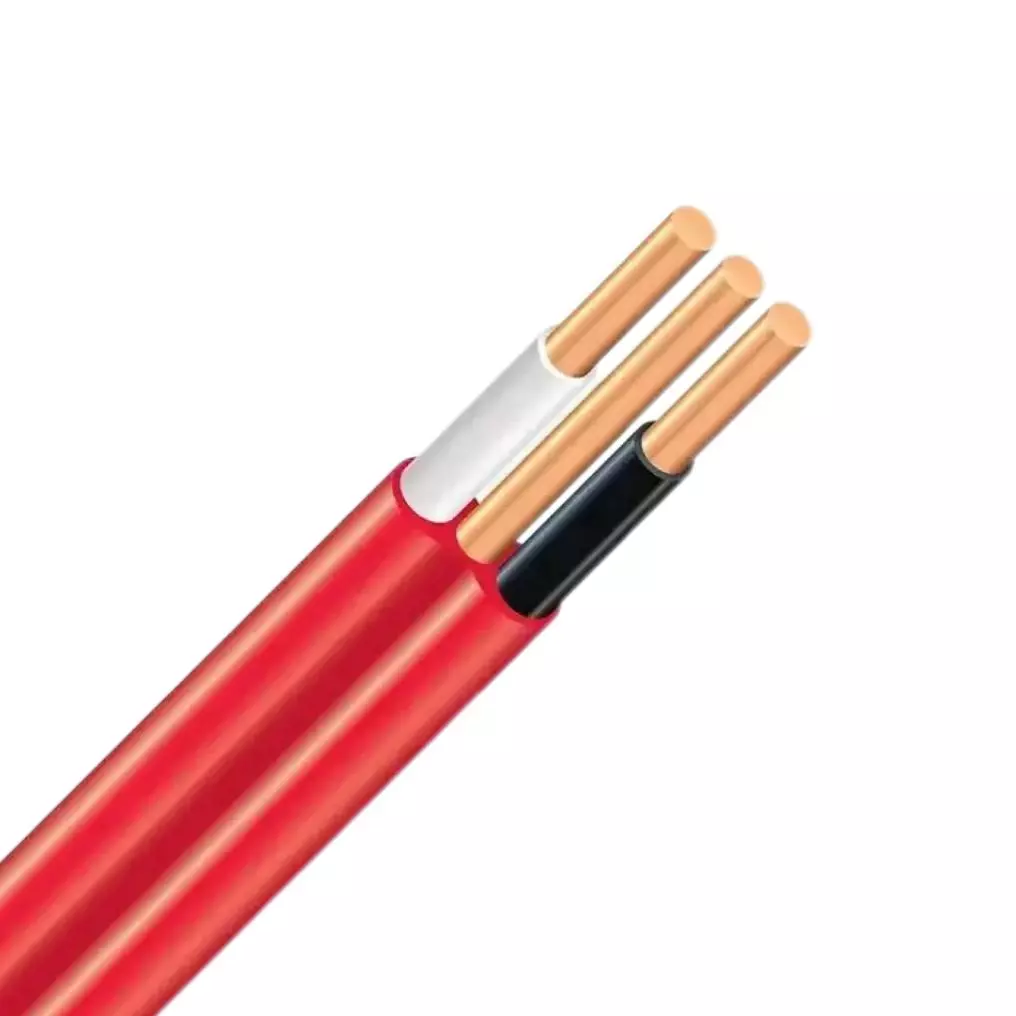

JACKET COLOUR CODE - Typical Application Guide

•WHITE - General Residential Wiring

•RED - 2 Black and Red conductors - 208V-240V Circuits (no neutral)

•ORANGE - No. 10 AWG General Residential Wiring

•YELLOW - No. 12 AWG General Residential Wiring

•BLUE - No. 14 AWG - 2 black and white conductors - 120V Arc Fault Circuit Interupter Applications

CABLE PRINTING

12 AWG 2 CDRS BLACK/WHITE NMD90 NYLON 300 VOLTS FT1

NMD90 jackets which reduces the coefficient of friction, allowing cables to be installed without external lubricants, resulting in reduced labour and materials costs.

Specification of Suke NMD90 Cable

|

Conductor

|

Insulation

|

Ground

|

Approx. Jacket thickness

|

Approx. Cable Dia.

|

Approx. Cable weight

|

Allowabl e Ampaciti

es 30°C

|

|

Size (AWG)

|

Cores

|

Strands

|

Inches

|

mm

|

Size (AWG)

|

Core

|

Inches

|

mm

|

Inches

|

mm

|

Ib/ 1000ft

|

Kg/ km

|

|

|

14

|

2

|

1

|

0.034

|

0.86

|

14

|

1

|

0.030

|

0.76

|

0.388*0.192

|

9.86*4.88

|

68

|

101

|

25*

|

|

14

|

2

|

1

|

0.034

|

0.86

|

14

|

1

|

0.030

|

0.76

|

0.388 x 0.192

|

9.86 x 4.88

|

68

|

101

|

25*

|

|

12

|

2

|

1

|

0.034

|

0.86

|

14

|

1

|

0.030

|

0.76

|

0.422 x 0.209

|

10.71 x 5.30

|

86

|

129

|

30*

|

|

10

|

2

|

1

|

0.034

|

0.86

|

12

|

1

|

0.030

|

0.76

|

0.481 x 0.230

|

12.21 x 5.84

|

122

|

182

|

40*

|

|

8

|

2

|

7

|

0.040

|

1.02

|

10

|

1

|

0.045

|

1.14

|

0.636 x 0.312

|

16.15 x 7.92

|

208

|

310

|

55

|

|

6

|

2

|

7

|

0.051

|

1.30

|

8

|

7

|

0.045

|

1.14

|

0.792 x 0.370

|

20.12 x 9.40

|

315

|

468

|

75

|

|

14

|

3

|

1

|

0.034

|

0.86

|

14

|

1

|

0.030

|

0.76

|

0.345

|

8.77

|

86

|

128

|

25*

|

|

12

|

3

|

1

|

0.034

|

0.86

|

14

|

1

|

0.030

|

0.76

|

0.381

|

9.69

|

114

|

169

|

30*

|

|

10

|

3

|

1

|

0.034

|

0.86

|

12

|

1

|

0.030

|

0.76

|

0.427

|

10.85

|

163

|

242

|

40*

|

|

8

|

3

|

7

|

0.040

|

1.02

|

10

|

1

|

0.045

|

1.14

|

0.570

|

14.47

|

275

|

408

|

55

|

|

6

|

3

|

7

|

0.051

|

1.30

|

8

|

7

|

0.045

|

1.14

|

0.695

|

17.65

|

421

|

627

|

75

|

|

3

|

3

|

7

|

0.051

|

1.30

|

6

|

7

|

0.080

|

2.03

|

0.925

|

23.48

|

799

|

1189

|

115

|

We have alarms on extruding insulation andjacket, to keep 100% quality.

Founded in 1994, Fujian Suke Cable Technology Co., Ltd. Decades of wire and cable manufacturing experience enables us to be one of Top 20 cable manufacturers in China. Our products cover low/medium/extra high voltage power cable, submarine cable, control cable, instrumentation cable, building wire, flexible rubber cable, fire rated cable, renewable cable, solar cable, industrial cable, LAN cable, coaxial cable etc, a total of nearly 30 series with 4,000 types and more than 50,000 specifications for various fields within over 100 countries.

10

No. of Production Lines:Above 10

7

Number of Foreign Trading Staff:7

3

The company has 3 factories

Our workshops and certifications

Our company has three plants possessing 200 square kilometers and over 4500 employees with 130 technicians creating annual export revenue exceeding 150 Million USD.

Also, our company has passed ISO 9001, ISO 14001, ISO45001, OHSAS18001,etc certificatiom, and has got CCC,TLC, TUV, VDE, UL, CE, SAA, BS etc. certificates for our products.

Building wire is generally used in house fixed wiring. It is PVC insulated unsheathed electric wire. The onstruction is CU/PVC.

How long is the transit period?

The transit time is usually around 15-25 days.

What is the policies and procedures related to returns, refunds, and warranties?

For all clients, usually we can offer a two-year warranty for all of products with correct installation and use, and refund or free more product offer, etc will be accepted too, if any issues happen within warranty period. Out of warranty period, we accept negotiation, if any need, with our clients under mutual agreement.

Conductor Structure of Power Cable

1. Conductors comply with IEC, AS/NZS and BSI standard requirements

2. The conductors of multi-core have different shapes. The single-core is circular. The shape of Multi-core cable with size up to and 35m2 can be circular, semicircular and fan-shaped, the conductor with size over and 50m2 are circular and semicircle.

3. A single core is allowed with size below 16m2. Conductor More than 25m2 are multi strands.

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address