Fire Resistant Cables Engineered to Meet Strict Safety Standards for Hazardous Applications Worldwide

Jun 12,2025

Jun 12,2025

Suke

Suke

Fire-rated cables are essential in hazardous areas because they are vital equipment to ensure operational safety. The cables are made to meet global safety standards and play an extremely important role during emergencies such as fires internal to a boat or other causes, where normal cables would simply add fuel to the flames.

The Importance of Fire-Rated Cables in Hazardous Areas

Fire-rated cables are specifically designed to maintain circuit integrity even when exposed to extreme heat or direct flames. This is of the utmost significance in hazardous environments, such as oil refineries and chemical plants, because electrical failures cause life-threatening consequences. While standard cables may combust or lose functionality at higher temperatures, fire-resistant cables remain consistently operational, ensuring critical systems remain powered whatever the urgent situation.

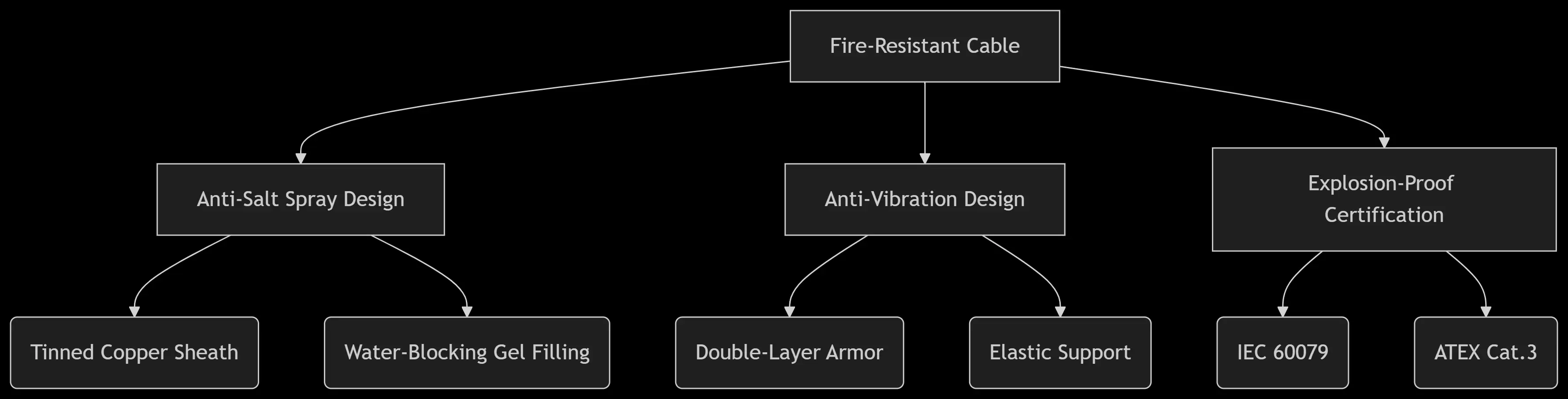

Engineering and Design of Fire-Rated Cables

Fire-rated cables derive their superior performance from their advanced design and material selection. Typically, these cables are constructed of materials that can withstand high temperatures, such as mica-based tapes, ceramic fibers, or specially formulated polymers. These materials act as insulators, preventing flames from propagating along the cables and maintaining electrical integrity even when exposed to fire.

An important design feature is their fire-rated sheathing. In most cases, these cables have an outer jacket made of cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR), which prevents ignition and also controls smoke output. Low Smoke Zero Halogen (LSZH) compounds are even preferred for fire protection, as they reduce harmful gas emissions into the air upon combustion, thus protecting the health of both firefighters and dwellers.

Compliance with International Safety Standards

Fire-rated cables must meet a range of international safety standards to ensure their reliability and performance. The International Electrotechnical Commission (IEC), Underwriters Laboratories (UL), and British Standards Institution (BSI) have all developed stringent testing regimes. The criteria applied in such testing cover the cables' ability to maintain continued service during fire exposure, the effects that fires have on them, and their smoke and harmful gas emissions. The IEC 60331 standard, for example, details requirements for cables that must maintain circuit integrity both during fire exposure and mechanical stress. Similarly, UL 2196 tests how well cables endure flames inside commercial and industrial buildings. Testing carried out under these regulations provides the ultimate reassurance to both regulators and users that these cables can perform when it matters most—when the lives of occupants and workers at a disaster scene are at stake.

Applications Across Industries

The fire-rated characteristics of cables make them applicable to a broad range of industries. In the energy sector, they are used in power plants and offshore drilling rigs, where the risk of fire is high, and the consequences of system failure for ecology or finance would be devastating. The transportation industry uses fire-rated cables in tunnels, airports, and on narrow-gauge railway systems, where uninterruptible power systems are vital to safety and operation.

In the construction of high-rise buildings and public infrastructure, non-combustible cables are indispensable. Used in hospitals, schools, and shopping centers, these cables maintain the uninterrupted operation of emergency systems, reducing danger to property and life. The wide range of applications demonstrates how vital they are in developing modern infrastructure.

Future Trends and Innovations

The development of fire-rated cables continues as technology advances. Researchers are looking for new materials and designs to further improve performance. Nanotechnology offers promise, potentially enabling cables with even greater high-temperature resistance and enhanced mechanical properties. Innovation in insulating materials and fire-rated coatings is underway, aimed at extending the duration they can function in a fire.

Another emerging trend is the integration of smart technology into fire-rated cables. Sensors embedded in these cables to detect temperature changes and fire outbreaks provide real-time data to building management systems. This proactive approach improves emergency response times and significantly enhances overall safety.

Finally, fire-rated cables are one of the foundations of safety in hazardous environments worldwide. Their advanced engineering, compliance with strict standards, and wide range of applications make them indispensable in preserving lives and infrastructure. As industries evolve, continued innovation in fire-resistant cable technology will help meet the expanding requirements—and new challenges—of safety and reliability.

Home

Home Explore High Quality PVC Power Wires Designed for Safety and Long-Lasting Performance

Explore High Quality PVC Power Wires Designed for Safety and Long-Lasting Performance  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address